Description

What are custom red Mylar bags?

Custom red Mylar bags are high-barrier pouches produced with red base films, inks, or accents. They protect products from oxygen, moisture, and light while giving you a strong red visual identity across sizes, formats, and SKUs in the same packaging system.

These bags use laminated structures for barrier and strength. Red can cover the full surface, sit in bands, or work as a focused accent. You choose size, thickness, finish, zipper style, and windows, then print your artwork around that red foundation.

Why do brands choose red on Mylar bags?

Brands choose red on Mylar bags to signal flavor intensity, fun, heat, strength, or urgency. Red attracts attention fast, helps products stand out, and makes lines easy to recognize in crowded shelves, menus, and ecommerce grids.

Red works across verticals: hot flavors, berry and cherry, “original” or hero SKUs, high-energy products, Valentine or holiday editions. It also pairs well with black, white, gold, and metallics, so you can build both mainstream and luxury looks on top of red foundations.

Common red color roles

- Spicy, bold, or “hot” flavors

- Strawberry, cherry, watermelon, and red berry profiles

- “Original” or flagship SKUs in a range

- Strength, power, or performance cues

- Love-, holiday-, or drop-driven limited editions

Which products fit best in custom red Mylar packaging?

Custom red Mylar packaging fits products where impact, flavor, and energy matter: gummies, candy, chips, hot snacks, sauces, jerky, energy products, pre-workouts, cannabis, vapes, and small cosmetics or beauty-driven lines.

Red helps signal intensity, fun, or indulgence before customers even read the label. It works for impulse buys, hero SKUs, and products built around flavor or performance. One red structure can support multiple flavors or strains with clear icon and text systems layered on top.

Great fits for red bags

- Gummies, chews, candy, and sour snacks

- Chips, spicy mixes, jerky, and bold snacks

- Cannabis flower, pre-rolls, and infused products

- Pre-workout, energy shots, and “pump” blends

- Lip products, nails, and other color cosmetics

How do red Mylar bags still protect product quality?

Red Mylar bags protect product quality using multilayer barrier films under the color. The red ink or film layer is visual; barrier layers behind it control oxygen, moisture, light, and odor transfer so products stay closer to launch quality through shipping and storage.

We match film spec and thickness to your category—snacks, cannabis, cosmetics, supplements—before discussing shade and finishes. You can go fully opaque for light-sensitive products or combine red with carefully sized windows where visibility matters and barrier still meets your targets.

Protection features

- High oxygen and moisture barrier laminates

- Opaque red builds for light-sensitive or discrete products

- Seal zones sized for real storage and shipping conditions

- Optional zippers for multi-use packs

- Inner surfaces compatible with food, beauty, or supplement products

What customization options can you add to red Mylar bags?

You can customize red Mylar bags by choosing shade, coverage, format, thickness, zipper type, window style, finish, and artwork. Red can be a full background, a top/bottom band, a flavor bar, or a set of icons, depending on how loud you want it.

We treat red as one attribute, not the whole story. Other attributes—matte vs gloss, metallic vs flat, simple vs illustrated art—decide whether bags feel mass-market, designer, exotic, technical, or natural.

Structural options

- Flat, stand-up, or gusseted red pouches

- Standard, wide-mouth, or child-resistant zippers

- Tear notches and optional hang holes

- Strip, shaped, or no windows

- Thickness tuned to weight, route, and handling

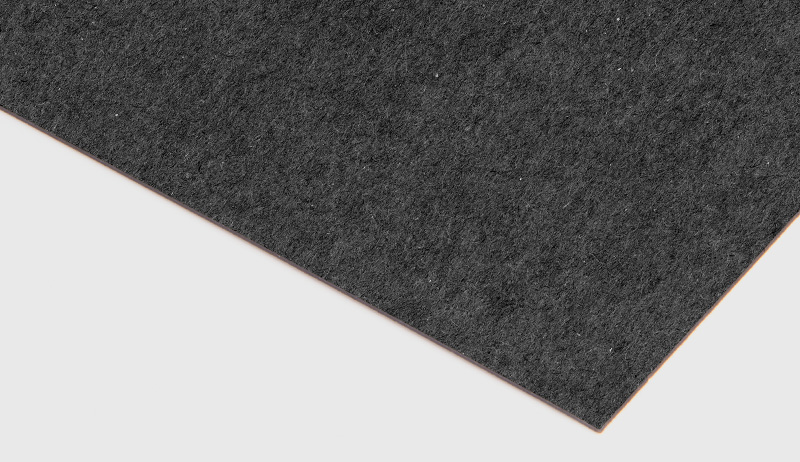

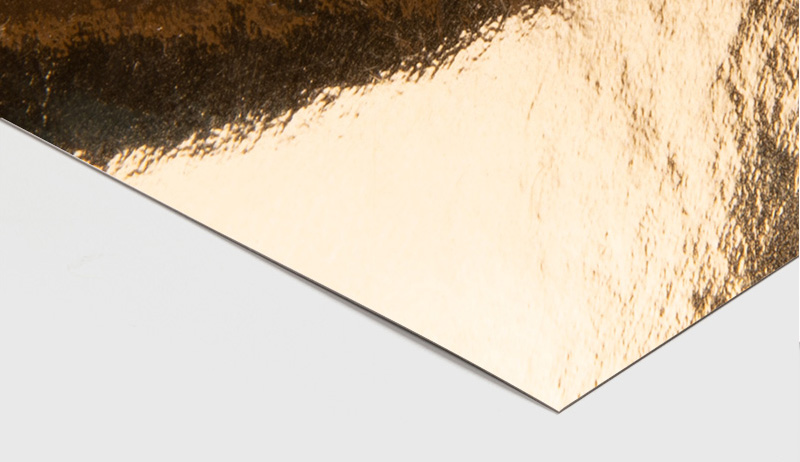

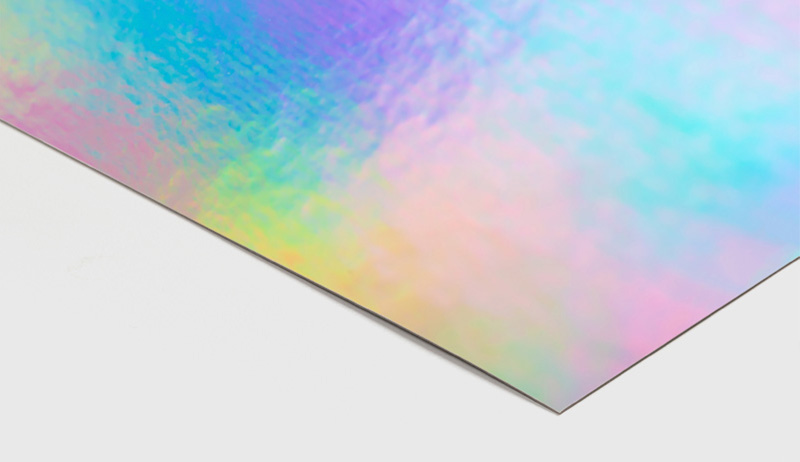

Visual and finish options

- Solid red backgrounds or partial panels

- Matte, gloss, or soft-touch red laminates

- Metallic or foil-style red highlights

- Color systems that use red vs other hues for ranges

- Space for logos, story, nutrition, and compliance

Can you match my exact brand red on Mylar bags?

Yes. We can match your exact red using Pantone or brand guidelines, then adapt it to print on chosen films and finishes so bags, boxes, and digital assets feel like one system.

We set clear specs, proof on the real substrate, and adjust for how red behaves on matte vs gloss vs metallic layers. Once locked, that brand red becomes a stable reference across reorders, new SKUs, and related packaging types.

Color-control steps

- Convert brand red into production-ready values

- Test and proof on your selected laminate and finish

- Adjust expectations for different surfaces and lighting

- Lock master red specs for ongoing runs

How much do custom red Mylar bags cost?

Custom red Mylar bag cost depends on bag size, film spec, zipper style, finishes, print complexity, and volume. Red itself doesn’t automatically cost more than other colors; cost increases mainly with special effects, many small SKUs, or heavier barrier and closure specs.

We usually offer a standard red option and a premium version: one efficient red build for core SKUs, and one with soft-touch, metallics, or mixed finishes for hero products or limited drops. You decide where red is just color and where it becomes a full designer element.

Key cost drivers

- Dimensions and laminate structure

- Plain red vs complex multi-color, multi-effect art

- Zipper and any child-resistant hardware

- Matte, gloss, soft-touch, or metallic extras

- Number of SKUs and quantity per design

How do you order custom red Mylar bags?

Step 1 – Define products and color role

- Product types and net weights per bag

- Red as master brand, flavor, strain, effect, or series

- Shelf life and storage conditions

- Sales channels: retail, ecom, subscription, wholesale

Step 2 – Lock structure and design

- Choose size, format, thickness, and closure

- Decide red coverage and any window strategy

- Receive dieline templates with clear color and safe zones

- Place logos, copy, red fields, icons, and mandatory info

- Approve digital proofs after preflight and color checks

Step 3 – Print, fill and restock

- Produce red Mylar bags to your spec

- Cartons arrive sorted by SKU/design

- Your team fills, seals, codes, and ships as usual

- Future SKUs reuse the same red spec and layout logic

Reviews

There are no reviews yet.