Description

What are custom clear Mylar bags?

Custom clear Mylar bags are high-barrier pouches made with transparent or semi-clear films so the product is visible inside. You choose how much to reveal, along with size, thickness, zipper, and print, while barrier layers still protect against oxygen, moisture, and handling.

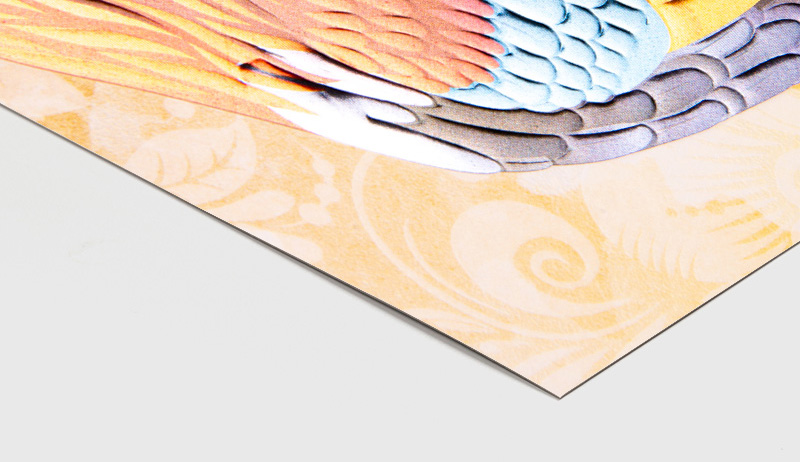

Clear structures let the product do part of the selling. Customers can read color, texture, and piece size at a glance, while you keep control of layout, branding, and mandatory information on printed areas, labels, or partial-coverage designs.

Which products work best in clear Mylar packaging?

Clear Mylar packaging works best for visually appealing products where appearance builds trust: gummies, candy, snacks, nuts, granola, coffee, tea, pet treats, dried fruit, bath salts, cosmetics, and some supplements. Customers see real texture and color instead of guessing from a photo.

Clear sections help reassure buyers that counts, piece size, shape, and color match expectations. They’re especially effective for mixed products—assorted gummies, snack mixes, blends—where contents look attractive and variety is part of the value proposition.

Popular use cases

- Gummies, chews, hard candy, and mints

- Nuts, trail mix, granola, and cereal snacks

- Coffee beans, tea, spices, and blends

- Pet treats and chews

- Bath salts, soaks, and cosmetic minis

- Capsules, tablets, and visually distinct supplements

How do clear Mylar bags still protect freshness and quality?

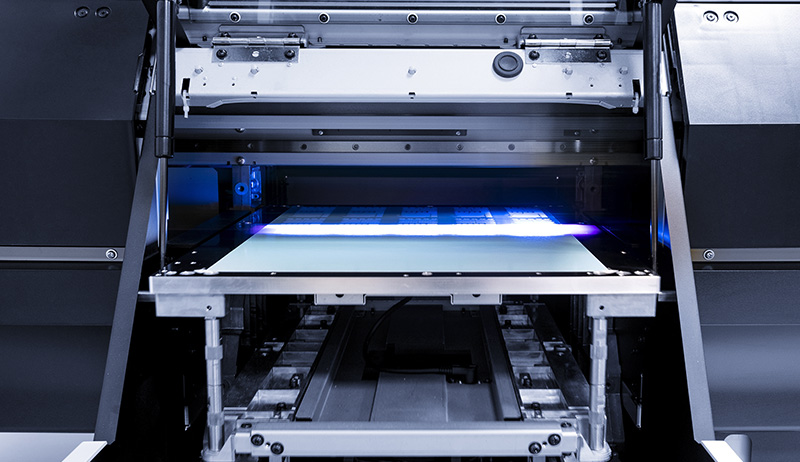

Clear Mylar bags protect freshness using engineered transparent barrier films that slow oxygen and moisture transfer while maintaining visibility. Laminated structures and strong seals keep texture, aroma, and color stable, even though customers can see the product through part or all of the pouch.

We match film spec to product and shelf life needs. For some items, we use high-barrier clear laminates; for more sensitive products, we combine clear windows with opaque barrier zones so you get both visibility and extra protection where it matters most.

Protection features

- Clear high-barrier laminates for oxygen and humidity control

- Optional mixed opaque/clear builds for light-sensitive products

- Strong seal zones sized for shipping and display

- Zippers for multi-use packs and resealing

- Interior surfaces tuned to your product category

Should you choose fully clear or windowed Mylar bags?

You choose fully clear Mylar bags when the whole product can be safely exposed to light and still look great, and windowed bags when you want visibility plus extra barrier on most of the surface. The right choice depends on product sensitivity and brand style.

Fully clear builds maximize trust and visual impact but give less room to hide scuffs or protect from light. Windowed builds frame the product in strips or shapes while the rest of the bag stays opaque for stronger protection and bolder branding areas.

Option breakdown

- Fully clear: maximum visibility, great for stable, colorful products

- Front window: strong branding plus a dedicated “view zone”

- Strip window: narrow band showing fill level and texture

- Shaped window: logo, icon, or theme cut-out over product

What customization options can you add to clear Mylar bags?

You can customize clear Mylar bags by adjusting clarity, size, format, thickness, zipper style, window design, finish, and print coverage. This lets you decide exactly how much product shows, how premium the pack feels, and how you balance branding with transparency.

We treat “clear” as just one attribute. Other attributes—gusset, closure, finish, color system, iconography—define whether your clear pack feels minimal, fun, luxury, clinical, or artisanal. You can run one structure and multiple designs across flavors, lines, and tiers.

Structural options

- Flat, stand-up, or gusseted clear pouches

- Standard, wide-mouth, or child-resistant zippers

- Tear notches and optional hang holes

- Full-front clear, partial clear, or narrow window

- Thickness tuned to product weight and fragility

Visual options

- Minimal branding over mostly clear film

- Bold top/bottom bands with a clear center panel

- Matte or gloss clear areas plus printed zones

- Color systems by flavor, strain, or formula

- Space for ingredients, nutrition, dosage, and story

Are clear Mylar bags right for every product?

Clear Mylar bags are not right for every product. Light-sensitive, very aroma-sensitive, or easily discolored items may need fully opaque or mixed constructions. In those cases, smaller windows or tinted clear areas can offer visibility without sacrificing too much protection.

We look at your product’s reaction to light, heat, and oxygen over time. If seeing the product is worth a slight trade-off in barrier, clear or windowed designs make sense; if stability is critical, we keep clear areas smaller and rely more on imagery and storytelling.

When clear makes sense

- Products stable under normal retail/household lighting

- Visuals (color, texture, pieces) drive purchase

- Trust and transparency are key to your brand story

When to limit clarity

- Highly light-sensitive or fragile products

- Long-term storage or harsh distribution routes

- Strong odor or flavor migration risk

How much do custom clear Mylar bags cost?

Custom clear Mylar bag cost depends on film type, clarity, size, thickness, zipper, window design, finishes, and order volume. Clear high-barrier films can be slightly more specialized than basic opaque films, but most pricing impact comes from structure, closures, and print complexity.

We can show scenarios: fully clear vs windowed vs mostly opaque with a small view panel. That lets you weigh cost, barrier performance, and visual impact for core SKUs, premium lines, and samples or mini formats.

Main cost drivers

- Clear barrier film spec and thickness

- Fully clear vs partial-clear vs small window

- Zipper type and any CR or tamper features

- Artwork coverage, colors, and finishes

- Quantity per SKU and number of SKUs per run

How do you order custom clear Mylar bags?

Step 1 – Define product and visibility goal

- Product type, fill weight, and visual appeal

- Desired visibility: full clear, window, or strip only

- Shelf life, storage, and shipping conditions

- Compliance, labeling, and branding requirements

Step 2 – Choose structure and layout

- Select size, format, thickness, and zipper style

- Decide clear vs opaque balance and window shapes

- Receive dieline templates with clear/print zones marked

- Place logos, copy, icons, and mandatory info

Step 3 – Print, fill and restock

- We produce clear Mylar bags to your spec

- Cartons arrive sorted by SKU/design

- Your team fills, seals, codes and ships as usual

- Reorders reuse locked specs; new SKUs reuse the same clear framework

Reviews

There are no reviews yet.